O2 Generator OxyGEN

GAZ SYSTEMES oxygen generators use PSA (Pressure Swing Adsorption) technology to produce medical grade oxygen of up to 96% purity.

OxyGEN generators have been developed with the aim of limiting maintenance operations: all consumables have been limited to a minimum. As such, our generators have not been fitted with membrane valves or electrochemical oxygen cells, which would both require annual replacement.

Technical characteristics

| Oxygen outlet pressure | 6 bar |

| Oxygen purity | 93% ± 3% and 95% ±1% |

| Oxygen flows | from 4 to 100 m3/h |

| Power supply | 220V 50 Hz |

| Inlet air pressure | > 7 bar |

| Connectivity | USB, Wifi, RJ45, Bluetooth & HDMI |

| Oxygen Analyzer | Zirconium * Paramagnetic |

| Touchscreen | 7" |

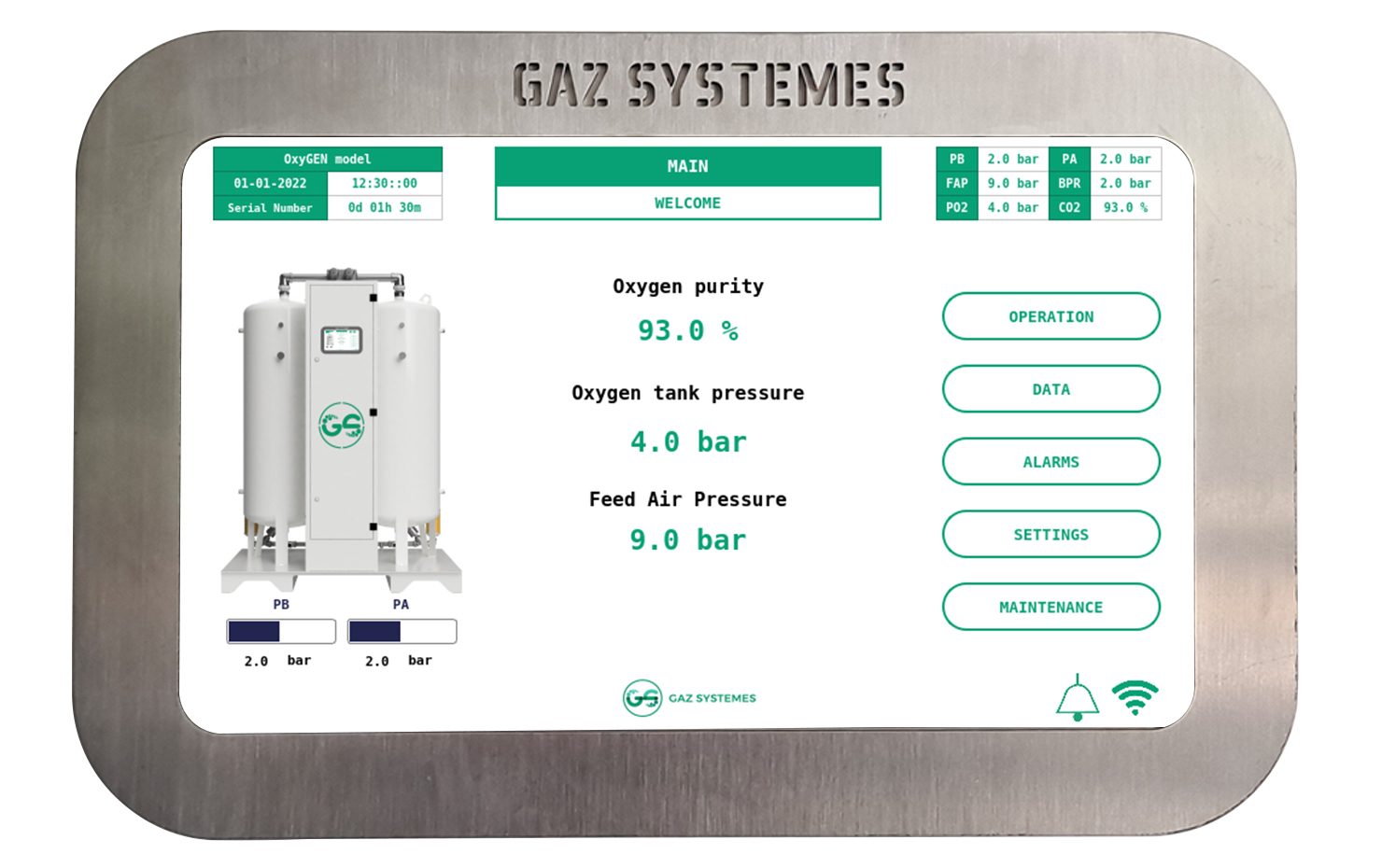

Human Machine Interface

Main Page

The human machine interface is user friendly. The home page gives access to all the information necessary for the user: all pressures are indicated in particular those in the compressed air tank and that in the oxygen tank. This allows at first glance to verify the proper functioning of the generator.

The application has a number of menus for managing factory and user parameters, alarms, and data recording.

Data-Logging – Statistics

The generator is capable of recording two years of data, knowing that each parameter is recorded every second. The saved parameters are:

- Pressure in column A

- Pressure in column B

- Pressure in the air tank

- Pressure in the oxygen tank

- Purity of oxygen produced

The recording of all this data makes it possible to anticipate breakdowns and resolve technical problems very quickly and safely.

All these data are very easily recoverable by the user: either by inserting a USB key in the PLC, or by entering an email address to receive the data files via email using a Wifi / Ethernet connection. The downloaded files can be used directly in data-processing softwares such as Excel.

Remote control

Our oxygen generators are easily accessible remotely through a secured internet connection. This service is included in all our generators without overcost and enables us to assist our customers in any way during the implementation or any maintenance operation.

Alarms Management

OxyGEN generators also record all the events likely to generate an alarm:

- Low pressure in the oxygen tank

- Oxygen concentration below threshold limits

- Fault on the refrigeration dryer

- Low inlet air pressure

All these events are recorded and accessible on the PLC for consultation or export by email or via a USB key.

Each of these events will set off visual and audible alarm signals.

Maintenance Management

As the maintenance of an oxygen generator is essential for its good long-term operation, the PLC are developed in order to be sure that the maintenance steps are carried out in due time by the operator of the generator.

A precise counter of operating hours is set up. It differenciates under voltage hours and under load hours.

Reminders can be set up with email notification several months before the mandatory maintenance milestones.